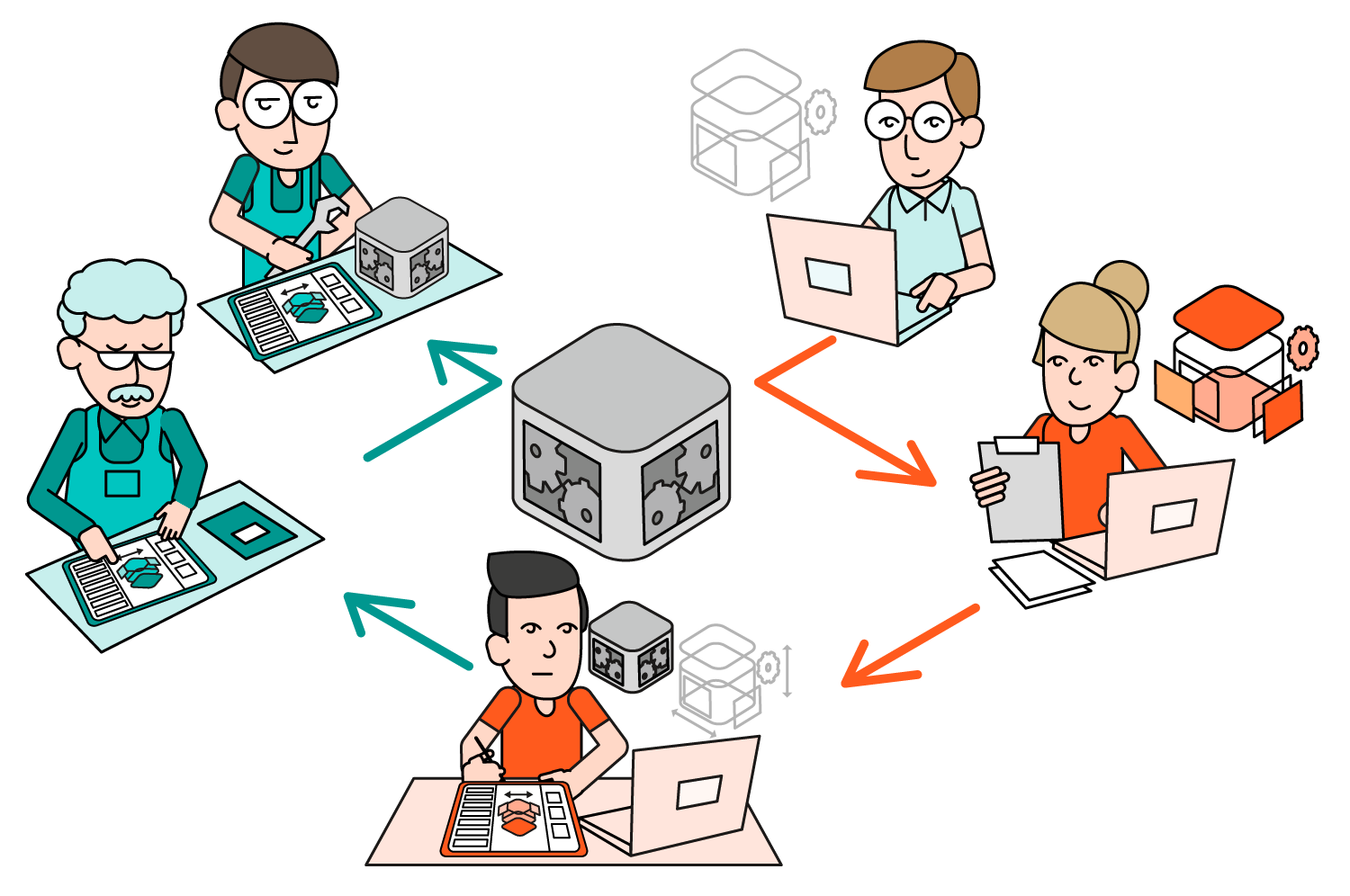

Tio-journey

Enough of the first impression. You want more? We offer every customer a free, no-obligation trial of our full solution. Don't hesitate, contact us now and get started today.

test Tio nowIf you don't want to wait long and want to get a feel for our solutions, we have prepared two not entirely serious simulators for you to try out. Here you can get an impression of Tio Assembly and TIO Player.

Take a look at the surface and edit a somewhat unusual product - a donut. Move the mouse over the surface and see what is possible with TIO.

try Tio assemblyIn our second simulator, you become a worker yourself and explore what Tio can look like on the store floor.

try Tio PlayerHave fun!

Our Customer

TESAT-Spacecom

- fast overview for the technician

- less inquiries

- an easy way to build 3D work plans

To increase our efficiency, we want to stop design construction drawings for our assembly team. So we searched for a tool to prepare the needed information in high quality and 3D. TIO helps us in the process of planning - we work directly on the 3D-data and are able to couple it onto SAP.