assembly instructions at Ruhrpumpen

Ruhrpumpen has several assembly plants worldwide. In Mexico, India, Germany, England or China, the pumps have to be assembled with consistent quality. To ensure this, employees in the work preparation department import the pump systems in 3D into Tio.

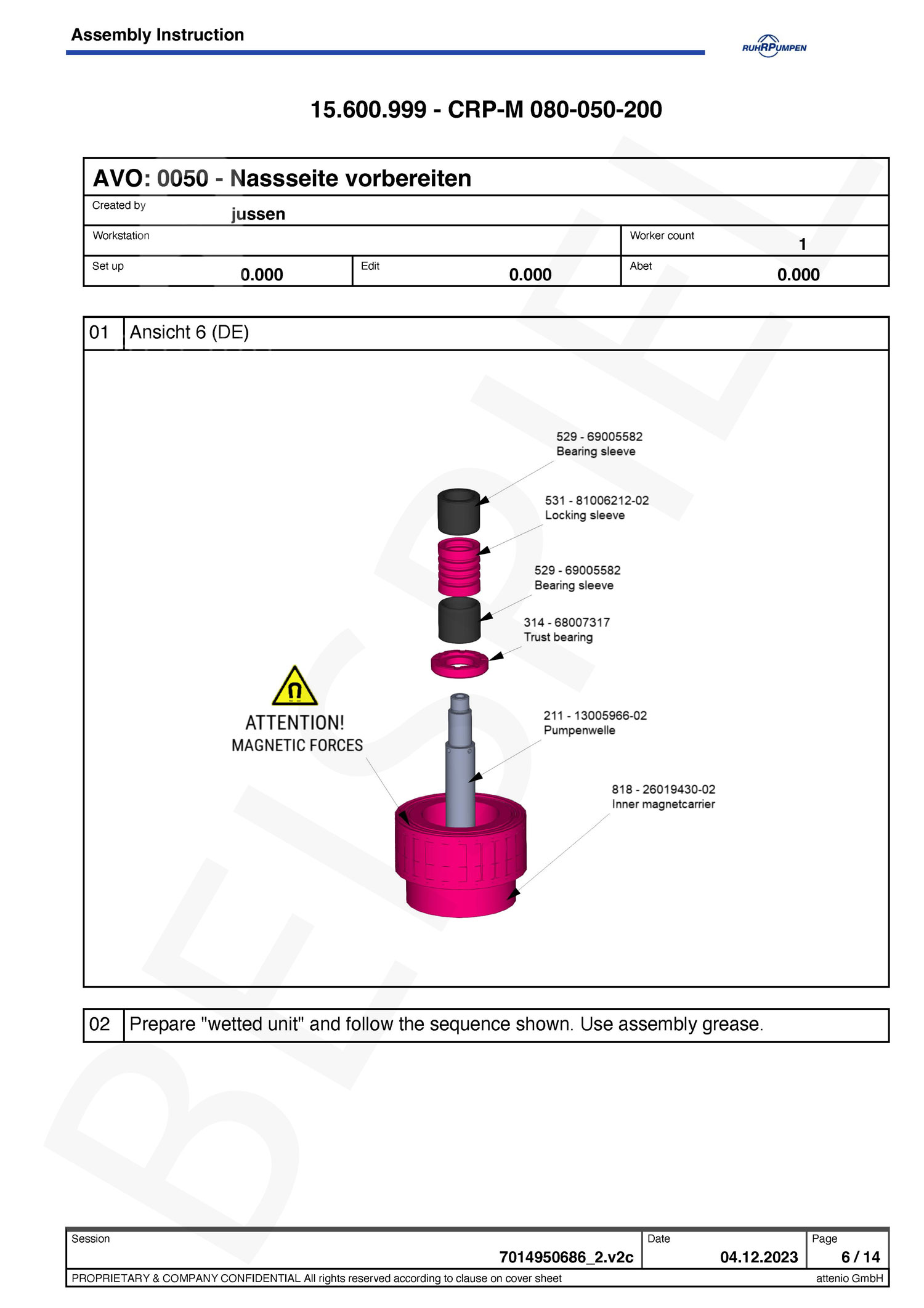

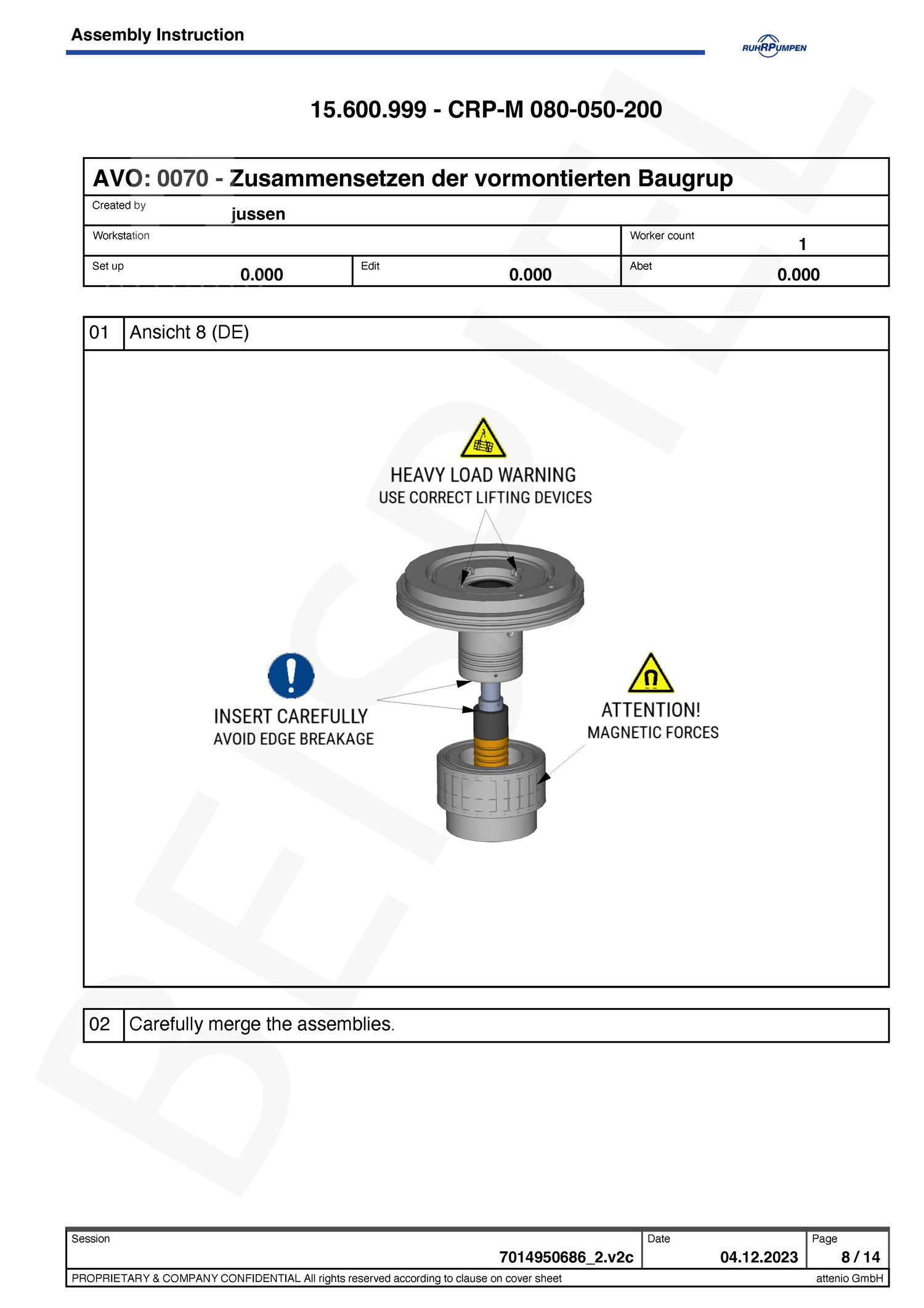

You first create the structure of the assembly instructions and use it to define individual work steps. You then create virtual views with information on material numbers, assembly instructions or the required tools. All of this before the first pump has been physically built. Just seconds later, the fitter in Mexico can call up the resulting instructions directly and digitally in their own language.

We at Ruhrpumpen were looking for a solution to be able to pass on product and project-relevant information globally in such a way that production sites with different boundary conditions, cultures, languages and technical requirements could also produce our "engineered to order" machines on time and thus satisfy our customers.- Christian Jussen, Group Manager Design & Development (2022) visit website

35% faster with Tio

35% faster with Tio

low effort

The consistent use of 3D models creates many advantages. Not only do you avoid media disruptions, but you can also plan and check your assembly at a much earlier stage. However, one of the main reasons for using 3D is the significantly increased productivity. Compared to assembly instructions created in MS Word with photos and screenshots, our customers are on average 35% faster with Tio.

The special thing:You don't need 3D know-how to create instructions with 3D. Tio has been developed for work planners, industrial engineers and foremen.They can quickly transfer their know-how to the assembly instructions.

The information is transferred to the store floor without any further effort, either as a PDF at the touch of a button or in digital form via the Tio 2 Connect Player.This ultimately saves the worker valuable time, as he has all the information at a glance thanks to the digital tool and if he is missing a view perspective or a unit of measurement, he can derive it directly from the 3D - queries are minimized and worker productivity increases.

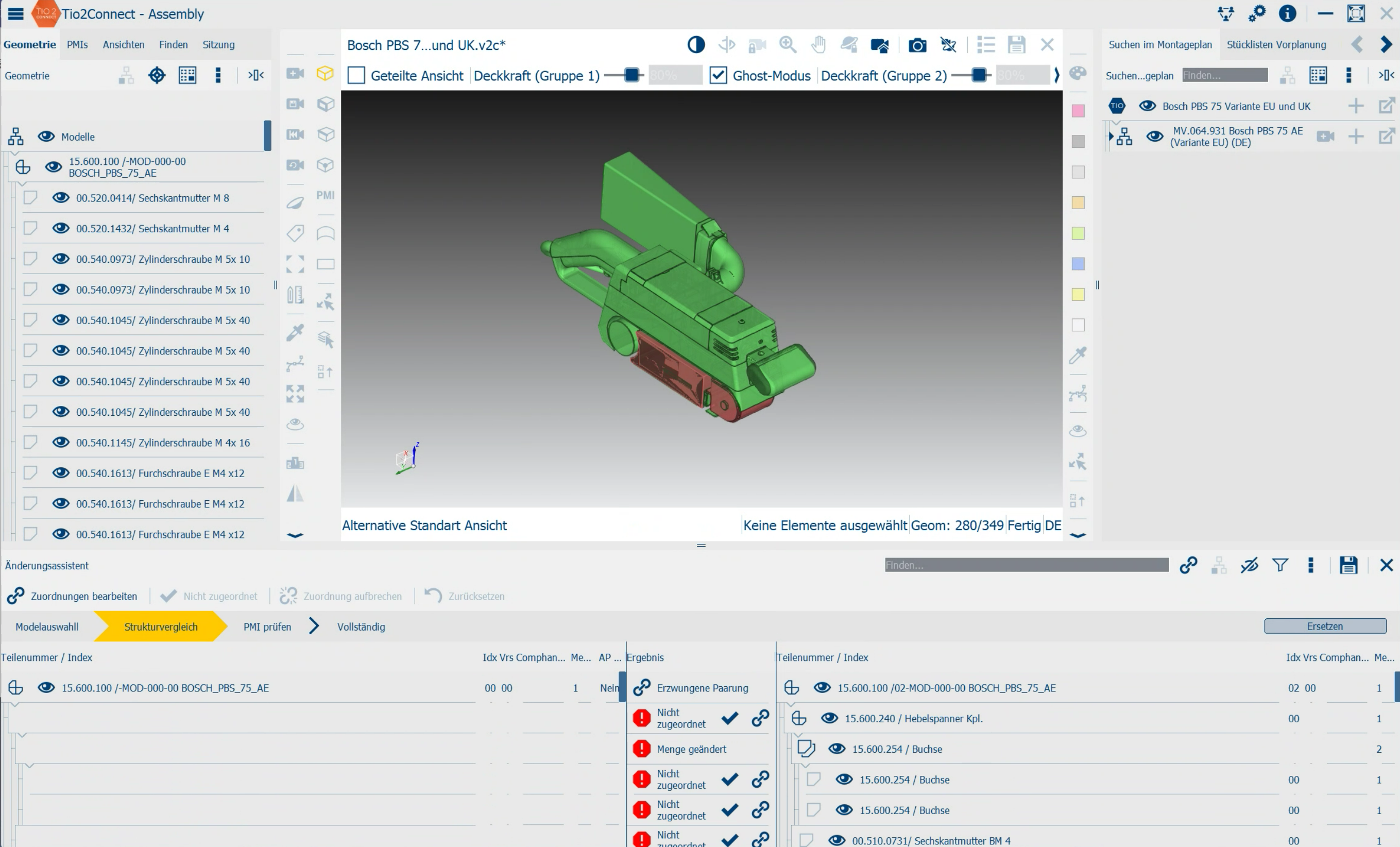

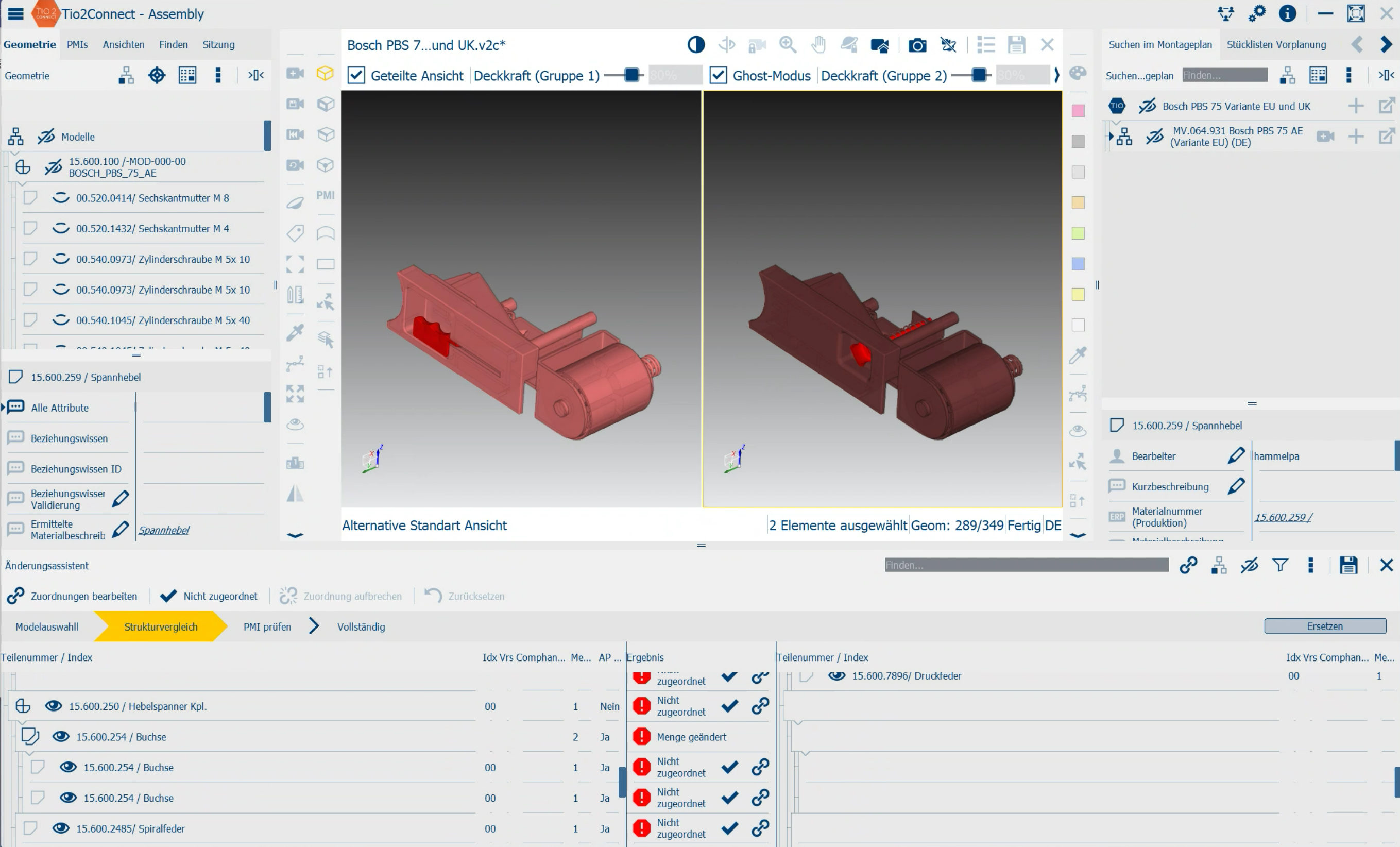

Changes

Dealing with changes and further developments is important for all companies and must not cause significant expense. Tio supports you with changes, visualizes them so that you only have to rebuild the changed components and can adopt the rest. To do this, Tio compares various 3D models according to configurable criteria (e.g. material numbers, geometry, revision). The user receives direct feedback in which unchanged components are displayed in green and changed components in red.

This procedure allows you to deal with changes in a way never seen before. Redline the changes in this form of presentation to highlight them and communicate them further or decide what impact these changes will have on your assembly instructions. Your instructions will be up to date again in no time at all.

Modular design

Tio is modular and adapts to your processes. Proceed step by step and start building your assembly instructions in Tio as a stand-alone solution. To do this, simply import a 3D model into Tio, create the instructions and export them as a PDF at the touch of a button.

In the next step, we integrate all plans and instructions into your databases. From now on, data is no longer written to the network drive; instead, all data is stored in the ERP or PLM with validity dates and in line with revisions. To exploit the full potential of digitalization, your fitters can now call up the instructions digitally. Of course, integration into an MES system or your own worker assistance system is also possible.

Information from the ERP is required for complete assembly instructions. With our interfaces, Tio can be fully integrated into your processes and the required information, such as standard times or material numbers, can be called up directly. This makes duplicate data storage or manual copying a thing of the past.

Multilingualism

Ruhrpumpen makes use of the various possibilities to create instructions in different languages in order to be able to carry out the planning in Germany or England. Assembly then takes place in Mexico or India. Tio understands various data languages and so the worker can use the instructions directly in the language he needs.

For free texts in the instructions, Tio offers the option of setting your own translations or completing them automatically using the integrated DeepL functionality. This means that with just a few clicks and very little effort, all information can be created directly in Tio, regardless of the work and country.

Integrated Translation in Tio

Integrated Translation in Tio

Process Integration

Tio's 3D viewer grows with your requirements. If you want to visualize certain attributes or parts list information, you can have them automatically prepared in the background so that they are immediately available at the right moment.

AutomationIf topics such as revision, validity or storage of data in databases are important, you benefit from standard interfaces to fully integrate the 3D viewer into your processes.

interfacesSupporting functions:

Create assembly instructions

Whether rough or down to the last detail - Tio is the tool for the efficient creation of instructions. Create work steps, document them and create the necessary views. Everything is created in just one system, giving you security in your processes and the necessary flexibility.

watch VideoVariants & changes

The change assistant specially developed by attenio creates unprecedented productivity. Variants, revisions or product changes can be compared with the original structure and you as the user only have to follow the changes in your planning; restructuring or planning is no longer necessary. You receive a complete overview of the product changes (geometric and structural) and can decide on a situational basis whether these have an influence on the content created or whether it is not relevant for assembly, for example.

watch VideoDocumentation

Tio has many functions for documentation. Choose from hundreds of templates, define your own texts, store documents or attach the material number or other metadata such as torques - all in different languages. Then illustrate it with specific views for optimum understanding on the store floor.

watch VideoResources

DManufacturing products requires more than just information about the product. Tio enables you to provide all the necessary documents, production resources, materials or other relevant information. If interfaces to the ERP are used, this information can be conveniently pulled directly from SAP, for example.

Demand-oriented export

The information created must cover a wide range of needs and reach a wide range of people. Tio offers various export options for further use of the information: Export your assembly instructions to PDF, transfer the work plans in full to the ERP, or display the content digitally in assembly.

watch VideoService

After delivery, products need to be serviced and repaired. Easily create service instructions in Tio or simply expand your assembly instructions. Do everything in just one tool, always with the support of the 3D product data model!

views

Photos of real assembly situations are extremely important for understanding colleagues on the store floor. Simply add these or supplement them with 3D views with helpful sections, exploded views or markups. This significantly increases the quality of the information generated.

watch VideoRed-Lining

Many different functionalities allow you to work directly on the 3D product data and document desired adjustments, for example: Set mark-ups, carry out measurements or attach photos. Tio is a simple communication platform, even between departments.

watch VideoChanges

"Nothing is as certain as the change" - the integrated change assistant compares different design statuses and evaluates the differences. View the product changes visually before taking a detailed look at the evaluation. Versioning, different material numbers, more recent approvals or a different supplier - the change wizard summarizes everything clearly.

watch VideoPerformance

We develop our solutions based on the requirements of the industry. Our customers' products range from compact devices consisting of just a few components to machines and systems that take up entire halls with 100,000s of components. The Tio products are powerful and convince in daily use.

Zum Feedbackthe Player

Tio is everything that is needed in assembly. Tio adapts to your assembly situation and therefore always provides the ideal interface and functions for your company. Tio adapts to your assembly situation and therefore always provides the ideal interface and functions for your company.

watch VideoAugmented Reality

2D, 3D or can it also be displayed directly on the real product? However you need your information, Tio always has the right form of visualization at the touch of a button. And all this without any time-consuming preliminary preparation - that's how we see the future.

watch VideoVariants & changes

The change assistant specially developed by attenio creates unprecedented productivity. Variants, revisions or product changes can be compared with the original structure and you as the user only have to follow the changes in your planning; restructuring or planning is no longer necessary. You receive a complete overview of the product changes (geometric and structural) and can decide on a situational basis whether these have an influence on the content created or whether it is not relevant for assembly, for example.

watch Video